Vanillin is an organic compound with the molecular formula ‹See Tfd›C8H8O3. It is a phenolic aldehyde. Its functional groups include aldehyde, hydroxyl, and ether. It is the primary component of the extract of the vanilla bean. Synthetic vanillin is now used more often than natural vanilla extract as a flavoring agent in foods, beverages, and pharmaceuticals.

Vanillin and ethylvanillin are used by the food industry; ethylvanillin is more expensive, but has a stronger note. It differs from vanillin by having an ethoxy group (−O−CH2CH3) instead of a methoxy group (−O−CH3).

Natural vanilla extract is a mixture of several hundred different compounds in addition to vanillin. Artificial vanilla flavoring is often a solution of pure vanillin, usually of synthetic origin. Because of the scarcity and expense of natural vanilla extract, synthetic preparation of its predominant component has long been of interest. The first commercial synthesis of vanillin began with the more readily available natural compound eugenol (4-allyl-2-methoxyphenol). Today, artificial vanillin is made either from guaiacol or lignin.

Vanillin crystals extracted from vanilla extract

Lignin-based artificial vanilla flavoring is alleged to have a richer flavor profile than oil-based flavoring; the difference is due to the presence of acetovanillone, a minor component in the lignin-derived product that is not found in vanillin synthesized from guaiacol.[4]

Vanilla was cultivated as a flavoring by pre-Columbian Mesoamerican people; at the time of their conquest by Hernán Cortés, the Aztecs used it as a flavoring for chocolate.

Vanillin was first isolated as a relatively pure substance in 1858 by Nicolas-Theodore Gobley, who obtained it by evaporating a vanilla extract to dryness and recrystallizing the resulting solids from hot water.[5] In 1874, the German scientists Ferdinand Tiemann and Wilhelm Haarmann deduced its chemical structure, at the same time finding a synthesis for vanillin from coniferin, a glucoside of isoeugenol found in pine bark.[6] Tiemann and Haarmann founded a company Haarmann and Reimer (now part of Symrise) and started the first industrial production of vanillin using their process in Holzminden, Germany. In 1876, Karl Reimer synthesized vanillin (2) from guaiacol (1).[7]

By the late 19th century, semisynthetic vanillin derived from the eugenol found in clove oil was commercially available.[8]

Synthetic vanillin became significantly more available in the 1930s, when production from clove oil was supplanted by production from the lignin-containing waste produced by the sulfite pulping process for preparing wood pulp for the paper industry. By 1981, a single pulp and paper mill in Thorold, Ontario supplied 60% of the world market for synthetic vanillin.[9] However, subsequent developments in the wood pulp industry have made its lignin wastes less attractive as a raw material for vanillin synthesis. Today, approximately 15% of the world’s production of vanillin is still made from lignin wastes,[10] while approximately 85% synthesized in a two-step process from the petrochemical precursors guaiacol and glyoxylic acid.[11][12]

Beginning in 2000, Rhodia began marketing biosynthetic vanillin prepared by the action of microorganisms on ferulic acid extracted from rice bran. At 700 USD/kg, this product, sold under the trademarked name Rhovanil Natural, is not cost-competitive with petrochemical vanillin, which sells for around US$15/kg.[13] However, unlike vanillin synthesized from lignin or guaiacol, it can be labeled as a natural flavoring.

Vanillin is most prominent as the principal flavor and aroma compound in vanilla. Cured vanilla pods contain about 2% by dry weight vanillin; on cured pods of high quality, relatively pure vanillin may be visible as a white dust or “frost” on the exterior of the pod.

It is also found in Leptotes bicolor, a species of orchid native to Paraguay and southern Brazil,[14] and the Southern Chinese red pine.

At lower concentrations, vanillin contributes to the flavor and aroma profiles of foodstuffs as diverse as olive oil,[15] butter,[16] raspberry,[17] and lychee[18] fruits.

Aging in oak barrels imparts vanillin to some wines, vinegar,[19] and spirits.[20]

In other foods, heat treatment generates vanillin from other compounds. In this way, vanillin contributes to the flavor and aroma of coffee,[21][22] maple syrup,[23] and whole-grain products, including corn tortillas[24] and oatmeal.[25]

Natural vanillin is extracted from the seed pods of Vanilla planifolia, a vining orchid native to Mexico, but now grown in tropical areas around the globe. Madagascar is presently the largest producer of natural vanillin.

As harvested, the green seed pods contain vanillin in the form of its β-d-glucoside; the green pods do not have the flavor or odor of vanilla.[26]

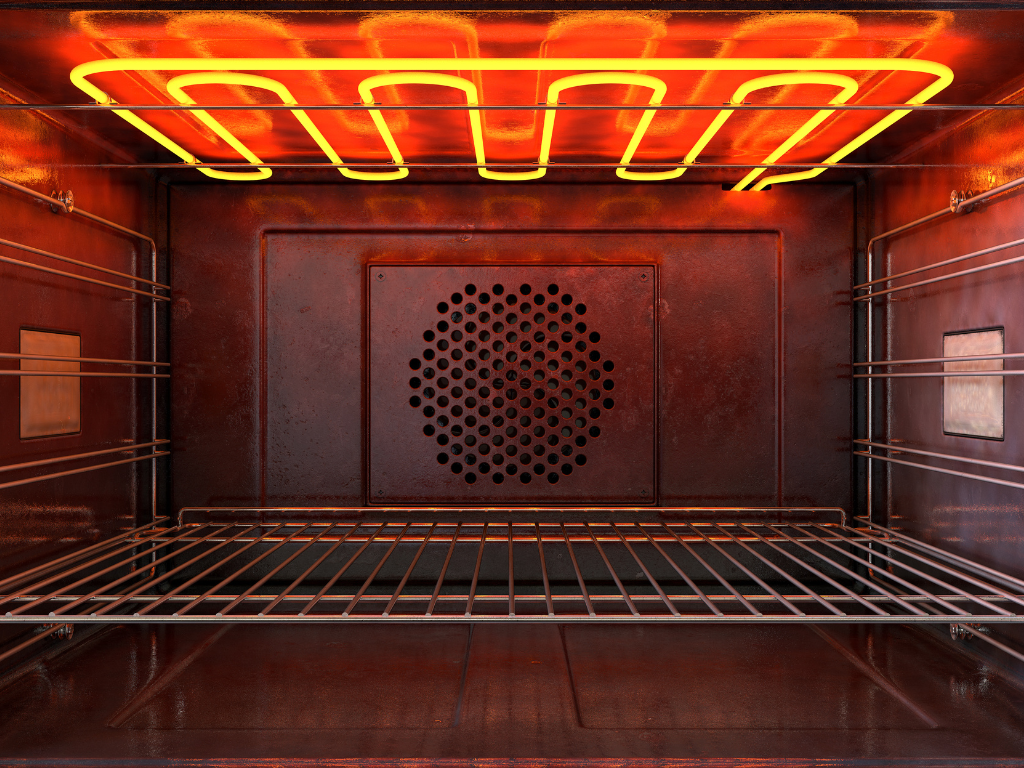

After being harvested, their flavor is developed by a months-long curing process, the details of which vary among vanilla-producing regions, but in broad terms it proceeds as follows:

First, the seed pods are blanched in hot water, to arrest the processes of the living plant tissues. Then, for 1–2 weeks, the pods are alternately sunned and sweated: during the day they are laid out in the sun, and each night wrapped in cloth and packed in airtight boxes to sweat.

During this process, the pods become dark brown, and enzymes in the pod release vanillin as the free molecule. Finally, the pods are dried and further aged for several months, during which time their flavors further develop.

Several methods have been described for curing vanilla in days rather than months, although they have not been widely developed in the natural vanilla industry,[27] with its focus on producing a premium product by established methods, rather than on innovations that might alter the product’s flavor profile.

Although the exact route of vanillin biosynthesis in V. planifolia is currently unknown, several pathways are proposed for its biosynthesis. Vanillin biosynthesis is generally agreed to be part of the phenylpropanoid pathway starting with l-phenylalanine,[28] which is deaminated by phenylalanine ammonia lyase (PAL) to form t-cinnamic acid. The para position of the ring is then hydroxylated by the cytochrome P450 enzyme cinnamate 4-hydroxylase (C4H/P450) to create p-coumaric acid.[29]

Then, in the proposed ferulate pathway, 4-hydroxycinnamoyl-CoA ligase (4CL) attaches p-coumaric acid to coenzyme A (CoA) to create p-coumaroyl CoA. Hydroxycinnamoyl transferase (HCT) then converts p-coumaroyl CoA to 4-coumaroyl shikimate/quinate. This subsequently undergoes oxidation by the P450 enzyme coumaroyl ester 3’-hydroxylase (C3’H/P450) to give caffeoyl shikimate/quinate.

HCT then exchanges the shikimate/quinate for CoA to create caffeoyl CoA, and 4CL removes CoA to afford caffeic acid. Caffeic acid then undergoes methylation by caffeic acid O-methyltransferase (COMT) to give ferulic acid. Finally, vanillin synthase hydratase/lyase (vp/VAN) catalyzes hydration of the double bond in ferulic acid followed by a retro-aldol elimination to afford vanillin.[29]

Vanillin can also be produced from vanilla glycoside with the additional final step of deglycosylation.[26] In the past p-hydroxybenzaldehyde was speculated to be a precursor for vanillin biosynthesis. However, a 2014 study using radiolabelled precursor indicated that p-hydroxybenzaldehyde do not synthesise vanillin or vanillin glucoside in the vanilla orchids.[29]

What is vanillin made up of?

Vanillin is a mixture of chemical compounds, of which vanillin and its hydrolysates (monomeric enantiomer and/or diastereomers) constitute the largest components, and some other compounds in lesser amounts. The predominant components are biochemically derived from the lignin and cellulose monomers in wood or in lignocellulose or chitin.

The structure of vanillin is complex, consisting at least of four groups: the sugar ring, hydroxyl group(s), a group called α-phosphate (which is a functional group having both pi-electrons and an oxygen lone pair), and other functional groups such as carboxylic acid and hydroxyl. Its chemical structure is:

Vanillin was first isolated from natural vanilla in 1874 by Bertolome Ferrero.[30] A second isolation procedure was described by Ferdinand Tiemann and Wilhelm Haarmann in 1886,[31] which is still the method used to obtain naturally occurring vanillin today. This method generally takes four months, but some producers are capable of producing it in less than two (taking advantage of fresh vanilla fruits). The cost of natural vanilla is high, making vanillin a popular alternative. In 1880, vanillin was synthetically produced for the first time by Ferdinand Tiemann and Wilhelm Haarmann.[31] It was produced as a yellow oil, which darkened upon standing due to oxidation.

Is vanillin a natural product?

Vanillin is a synthetic product made by the oxidation of vanillin-14,14′-dideoxy-2,3,4,5,6-pentaerythritol. Synthetic vanillin is obtained from natural vanilla using highly corrosive hydriodic acid in the presence of caustic soda and an iron catalyst. This method was invented by Ferdinand Tiemann and Wilhelm Haarmann in 1886.[32]

Besides being a common flavor component of many processed foods [33] and an important ingredient in foods such as ice cream, vanilla extract is also used as a component of many perfumes.[34] Vanillin was also synthesized from sugar in the early 1900s.

Due to the high price of natural vanilla, synthetic vanillin and vanillin-rich extract were developed in the mid-19th century. Synthetic vanillin was invented by Tiemann and Haarmann.[31] Vanillin-rich extract is made by vacuum distilling waste paper and pine bark. Today, it is produced mainly from petrochemicals.[7]

Vanilla flavor was first patented in 1874 as a result of research to develop artificial and more cost-efficient vanilla flavor for the manufacture of chocolate, caramel, and confections.[35] Since its creation, artificial vanilla flavor has become an integral part of processed foods ranging from baked goods to frozen dairy desserts to soft drinks such as cola.

Is vanilla and vanillin the same?

Vanilla and vanilla essences are two closely related compounds that may sometimes be confusingly spelled and used interchangeably. They refer to different types of extracts from the vanilla bean. Vanilla essence is a synthetic imitation, generally derived from ethyl acetate or ethyl alcohol, which is an extract of the aromatic seeds of the orchid plant; vanilla extract is a combination of about 30% whole vanilla beans with alcohol and water, plus various other ingredients including glycerin, water, sugar, vanillinoids and flavoring oils.

The essence refers to what one might find in a spoonful of vanilla ice cream, while the extract refers to what one might find in a bottle labeled as “vanilla extract.” Vanilla essence is a much more concentrated version of vanilla flavoring, and it is often dissolved in water and added to food after cooking. Vanilla extract is also used as a flavoring agent, but it can be used in cooking as well.

Is vanillin different from vanilla extract?

Vanilla extract refers to commercial products that are made from the vanilla bean. These products contain the vanilla bean along with one or more alcohols. There are two types of vanilla extracts, Bourbon and Tahitian, with Bourbon being the most popular. The Tahitian variety contains more vanillin than the Bourbon variety; however, this type of extract has been substituted by synthetic flavorings because it does not have the same flavor profile.

What is the origin of vanillin in vanilla?

Vanillin is first synthesized as a triterpene compound and is then formed into vanillin by hydrolysis. After the synthesis of vanillin, it is oxidised to yield vanillin by some unknown mechanism. Vanillin has been found only in the flowers and stems of various species of orchids such as vanilla.

How is natural vanillin made?

Vanilla is the source of many flavor compounds; these include vanillin, anethole, and coumarin. Vanilla beans are harvested while they are still green. Vanilla pods are later dried in the sun or under artificial light to facilitate fermentation by micro-organisms, including fungi and bacteria. The resulting product is dark brown to black in color and its consistency is brittle like chondrillite. These microorganisms can be intentionally used to inoculate vanilla beans in addition to or in place of the natural fermentation process.

What is ethyl vanillin made of?

Vanillin is a natural-source aromatic substance obtained from ethyl vanillin by the action of alcoholic fermentation and hydrolysis in the presence of microorganisms. It is extensively used in food flavoring and fragrance, cosmetics, medicines, and synthetic materials.

Vanillin has a strong odor which closely resembles that of vanilla. It has a sweet taste and its melting point is 88°C (190°F). Vanillin is colorless and transparent liquid with low solubility in water. The molecular weight of vanillin is 142.25 g/mol and the molecular formula C10H16O2 . The molecular formula for vanillin is CH3CHOHCH2O2 .

Vanillin is a component of the vanilla bean and it is synthesized from vanillin-14,14′-dideoxy-2,3,4,5,6-pentaerythritol as well as from guaiacol. The major source of vanillin currently used in the food and beverage industry is synthetic vanillin. Natural vanilla flavor is high in cost while synthetic vanilla flavor has a more affordable price and can be found in many processed foods.