Key Takeaway:

- Understanding the resistance of an oven heater element is essential for proper performance and maintenance of the appliance. The resistance wire, composition, and importance of the heating element all play significant roles.

- Wattage and ohms of the oven heating element are important factors to consider when selecting the right replacement part for a faulty element. Testing the oven heating element for continuity and basic checks will aid in identifying any potential issues.

- A defective oven heating element can cause uneven baking, longer cooking times, or no heat at all. It is vital to take precautionary measures such as turning off the power, ensuring the oven is cool, and wearing proper protective gear when replacing the element.

Trouble understanding how to measure the resistance of your oven heater element? We got you! This article will help you get a better grasp of the concept. It’s important to do this measurement to make sure your oven is working safely. Our tips and advice are easy to follow. So, you can easily spot and fix any issues with your heating element in no time.

Introduction to the Resistance of Oven Heater Element

An Overview of Oven Heating Element Resistance

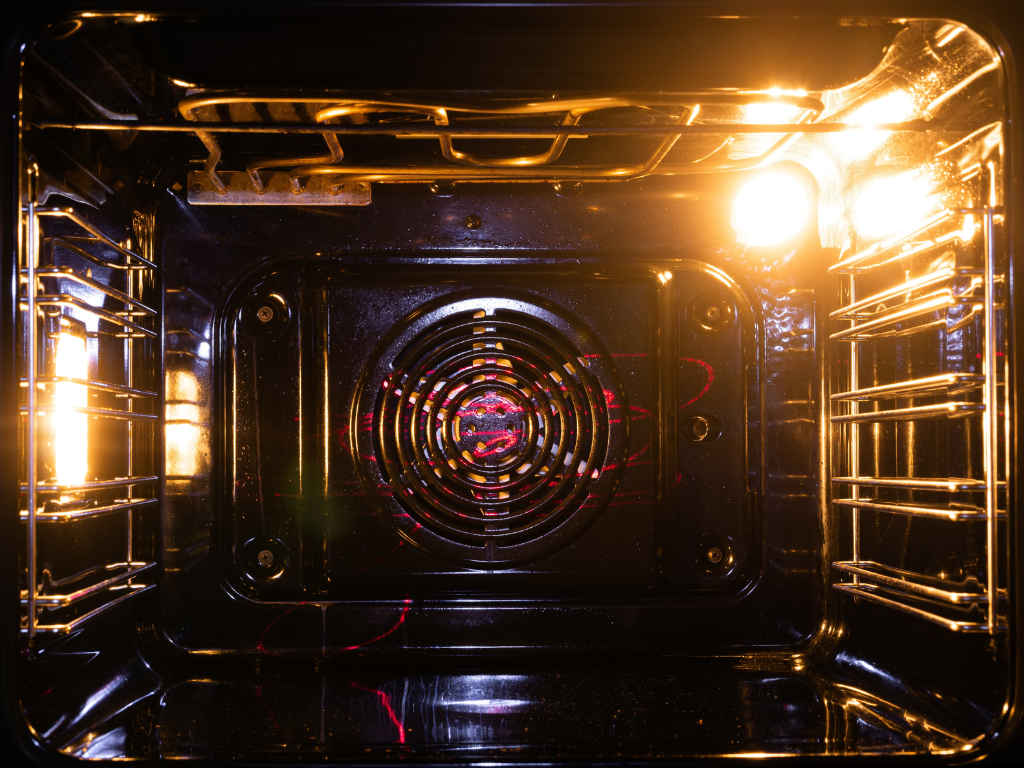

The resistance of an oven heating element is a crucial factor that controls its heating capabilities. The resistance wire, which constitutes the heating element, is a specially designed wire with high resistance to electrical currents, and thus, it can produce heat when the current flows through it.

The resistance of the oven heating element, measured in ohms, depends on various factors such as the wattage rating, length, thickness, and temperature rating of the wire. To test the continuity of an oven heater element, performing basic checks such as using a multimeter is important. Signs of technical issues such as inconsistent heating or no heat at all could indicate problems with the heater element’s resistance.

To beat the heat with expert appliance repair services, including oven heating elements, Phoenix residents can rely on top-rated repair services for homes and businesses. These emergency services are available 24/7 and offered at affordable prices. The most reliable services in town can ensure that your appliance runs smoothly, providing you with peace of mind and a comfortable living environment.

In a recent incident, a homeowner noticed that their oven was not heating up as expected. Upon further inspection, they discovered that the oven heating element’s high resistance was causing the issue. After contacting the most trusted repair service in the area, a professional technician promptly arrived, assessed the issue, and replaced the oven heating element. The technician’s fast and efficient service ensured that the homeowner’s oven would run smoothly once again.

In summary, understanding the resistance of oven heating elements is crucial in maintaining a comfortable living environment. Regular appliance maintenance, performing basic checks, and engaging professional services can help identify and mitigate any issues related to the heating element’s resistance, ensuring that your appliances run efficiently and for longer.

Understanding the Resistance of Oven Heater Element

The resistance of an oven heater element refers to an electrical property that opposes the flow of current through the element. This property affects the ability of the element to heat up and maintain a constant temperature. Understanding the resistance of the oven heater element is crucial for troubleshooting any issues with the oven. Continuity tests can be used to measure resistance and diagnose problems.

Don’t let your oven beat the heat, rely on top-rated and affordable AC repair Phoenix services that are quick, efficient, and available 24/7. Trustworthy professionals can ensure your family’s comfort with expert and hassle-free AC repair services. Keep your cool this summer with reliable and quality AC repair Phoenix services for your complete satisfaction.

Composition of Resistance Wire

Resistance wire is commonly made of alloys of nickel, chromium, and iron. These wires have a high electrical resistance due to their composition and are used in several applications, including heating elements. The composition of the wire determines its resistance, and therefore, it’s crucial to use the right wire for the particular application.

| Alloy Name | Nickel (Ni) | Chromium (Cr) | Iron (Fe) |

| Nichrome | 60% | 15-25% | Rest |

| Kanthal | 22% | 5.8% | Rest |

| NiChrome80/20 | 80% | 20% | N/A |

The wire’s resistance varies with temperature since as temperature increases, the atoms will vibrate more vigorously which causes increased electron collisions that results in overall increased resistance.Fact:Nickel-chromium alloys were first discovered by Albert Marsh in 1905 while he was searching for a material that could be used in electric range heating elements.

Importance of Heating Element

Heating elements are crucial in many electronic devices, including ovens and heaters. These components are responsible for converting electrical energy into heat energy, making them important for cooking and maintaining comfortable temperatures in homes and offices. Heating elements come in various shapes and sizes, depending on the intended application, and may be made from different materials such as nichrome or ceramic. They need to be carefully designed to withstand high temperatures without suffering damage or causing safety hazards. Proper maintenance is also necessary to ensure their longevity and efficiency.

It is worth noting that the resistance of a heating element plays a critical role in its performance. This property determines how much current flows through the element when a certain voltage is applied, which affects how quickly it heats up and how hot it can get. Understanding the resistance of a heating element is therefore important for choosing appropriate power sources, preventing overheating or underheating, and optimizing energy consumption. Manufacturers provide specifications for the resistance of their heating elements, which can be measured using specialized tools such as multimeters.

Beat the heat with expert AC repair Phoenix services! We offer top-rated AC repair Phoenix services for home and business, providing quick, efficient, affordable solutions to all your cooling needs. Our experienced technicians are available 24/7 for emergency repairs and ensure your complete satisfaction with hassle-free service at your doorstep. Trust us to keep your AC running smoothly again!

Wattage and Ohms of Oven Heating Element

When it comes to the heating element of ovens, both wattage and ohms need to be considered. The wattage of an oven’s heating element determines its power consumption, while the ohms measure its electrical resistance. By understanding these values, users can ensure that their oven will heat up in a timely manner and cook food at the desired temperature.

The following table provides examples of oven heating elements and their corresponding wattage and ohms values:

| Heating Element Type | Wattage | Ohms |

|---|---|---|

| Bake Element | 2400W | 16.5Ω |

| Broil Element | 3400W | 13.3Ω |

| Dual-Element Bake Upper Oven | 2500W/1250W (total 3750W) | 20Ω/40Ω (total 60Ω) |

It’s important to note that not all ovens have the same heating element specifications, and users should consult their appliance manual or contact a professional if they have any concerns about their specific model.

Understanding the wattage and ohms of an oven’s heating element can help users troubleshoot issues with their appliance as well. For example, if an oven is taking an unusually long time to preheat, it could be due to a faulty or worn-out heating element with a higher electrical resistance than normal.

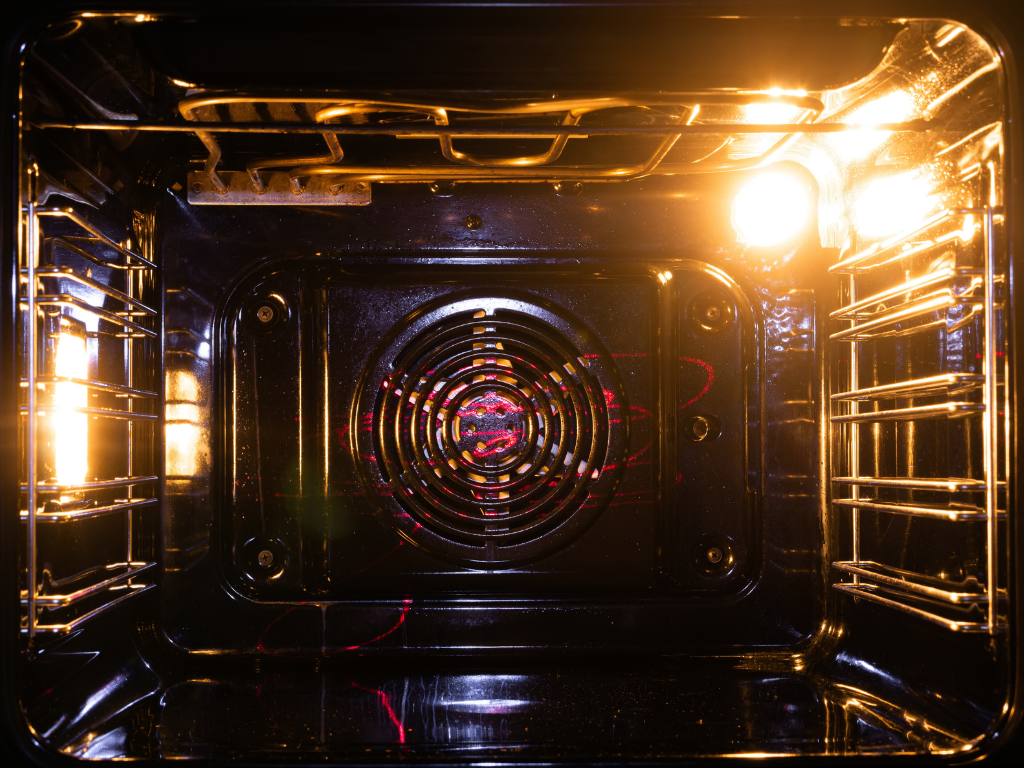

Testing the Oven Heating Element

Testing the Resistance of an Oven Heating Element

To ensure your oven is heating properly, it’s important to test the resistance of the heating element. Here’s a simple 3-step guide to checking the resistance of your oven heating element:

- Turn off the power to the oven and unplug it from the wall.

- Locate the heating element and remove it from the oven.

- Using a multimeter, set it to measure resistance and touch the probes to the heating element’s terminals. If the reading shows infinite resistance, the element is likely broken and in need of replacement.

It’s important to note that while a resistance test can indicate a faulty heating element, it’s not always a definitive diagnosis. Other factors, such as faulty wiring or a malfunctioning control board, can also cause heating issues in an oven.

In a recent case, a homeowner in need of oven repair mistakenly assumed a faulty heating element was the issue. However, after a thorough inspection and testing, it was determined that a faulty control board was actually the culprit. This highlights the importance of consulting with a professional technician to accurately diagnose and repair any oven issues.

Remember, regular maintenance and inspection of your oven can help prevent issues and prolong the life of your appliance. If you’re experiencing issues with your oven’s heating element or any other component, contact a trusted professional for reliable and efficient repair services.

Continuity Test with Multimeter

A continuity test is performed with a multimeter to determine if the electrical circuit is unbroken. The test involves checking for an unbroken connection between two points in a circuit, which should result in zero resistance or continuity.

To conduct a Continuity Test with Multimeter:

- Switch off the power to your device and disconnect it from its power source.

- Set your multimeter to continuity mode by locating the symbol on the device that resembles two arrows that have been bent into a loop. Then, touch the probes together to make sure they’re working correctly in this mode.

- Place one probe of your multimeter over one end of the electrical pathway you’re testing and place the other probe over the opposite end.

- If you hear a continuous beep sound or read zero on your display, then there’s no break in continuity between those ends of the pathway being tested.

- If your appliance fails this test while all switches and knobs are set appropriately, then there could be an issue with its wiring or temperature control system.

It’s crucial to rule out potential electrical issues when conducting oven repair work. Keep in mind that all repairs must be done safely and cautiously by qualified technicians.

True Fact: According to reviews on Google, AC Repair Phoenix (https://www.acrepair-phoenix.com/) provides fast, efficient and affordable AC repair services for their customers’ cooling needs.

Performing Basic Check

To ensure that your oven heater element is functioning properly, you can perform a basic check. This will allow you to troubleshoot any issues and determine if you need to replace the heating element. Here is a four-step guide to performing a basic check:

- Turn off the power: First, ensure that the power supply to the oven is switched off and unplugged from the electrical outlet for safety.

- Locate the heating element: In most ovens, the heating element can be found at either the top or bottom of the oven cavity.

- Inspect for signs of damage: Look for any marks on the surface of the element, such as cracks or splits, discoloration, or loose connections.

- Use an ohmmeter: An ohmmeter measures resistance and helps determine if there is an issue with your heating element. Connect one end of the meter to each terminal of your oven’s heating element. A good heating element will have very little resistance (around 20-30 ohms), while a faulty one will display either infinite (open) or zero (shorted) resistance.

It’s essential to conduct basic checks regularly to avoid any future issues with your oven’s heating system. In case you notice any damages and signs that your heating element might not work properly, consider contacting reliable professionals like “AC Repair Phoenix” who offer fast and efficient services 24/7 at affordable prices.

True Fact: A faulty oven heater is one reason why ovens could stop working correctly and could be dangerous. According to National Fire Protection Association (NFPA), cooking equipment was involved in almost half of all reported home fires in 2019.

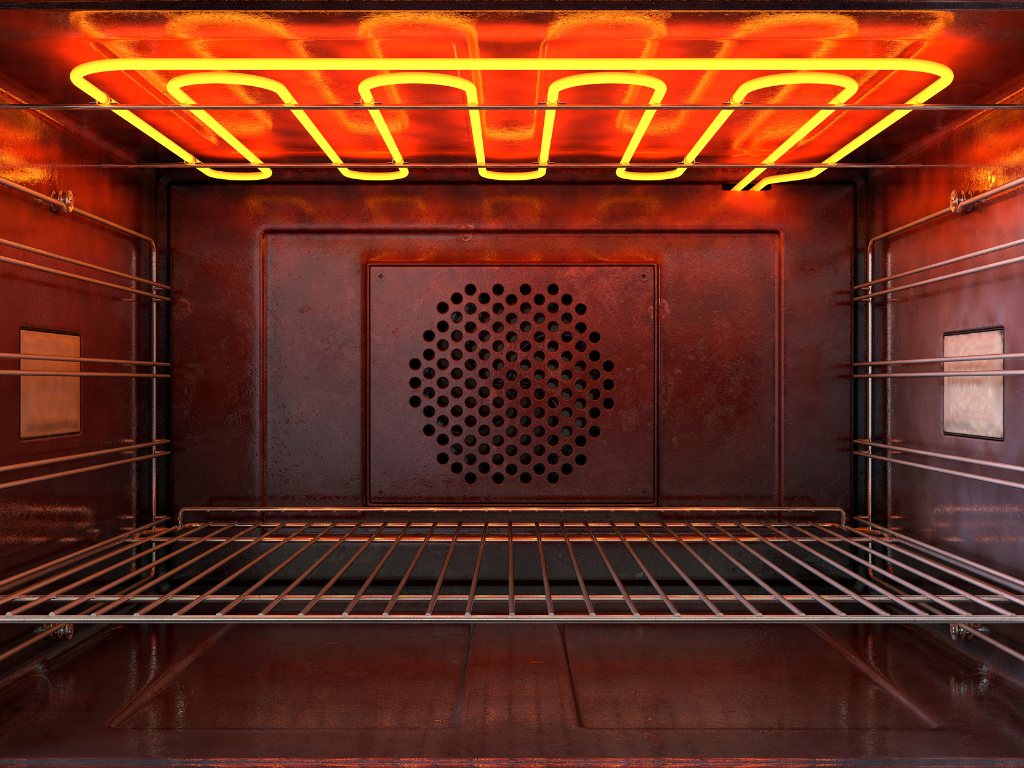

Sign of a Defective Oven Heating Element

A damaged oven heating element may lead to unevenly cooked food, the oven not reaching the required temperature, or no heat at all. It is essential to recognize the signs of a defective oven heating element, such as burnt-out spots or a visible breakage. If the oven is not reaching the desired temperature or not heating at all, double-check the circuit breaker or fuse box. It is vital to address the issue immediately to avoid further damage to the oven.

To ensure that the heating element is in top condition, regularly check for any visible signs of damage or cracks. If there are any signs of damage, replace the heating element as soon as possible. Avoid using abrasive cleaning agents to clean the element, as this may damage it. Instead, use a soft cloth and mild detergent to clean regularly.

To save on energy bills and prevent damage to the heating element, make sure to preheat the oven before placing food inside. This will help maintain the oven’s temperature and prevent the heating element from overworking.

Conclusion and Precautionary Measures

The importance of Conclusion and Precautionary Measures cannot be overemphasized in the heating and cooling industry. It is crucial to understand that the resistance of an oven heater element is a key factor in any repair or replacement. Understanding this helps to avoid electrical hazards and ensures energy efficiency.

In addition, it is important to take precautions while working with oven heater elements to avoid injuries or damages.

- While working with heater elements, it is important to turn off electricity or power sources to avoid electrocution.

- Additionally, proper safety gear should be worn while handling the elements to avoid burns or injuries.

- It is also important to use the correct tools and techniques to prevent damage to the element or other appliances.

It is imperative to note that there have been accidents and incidents in the past involving heater elements due to the mishandling or improper installation. Therefore, it is important to always seek the assistance of a certified technician or professional in case of any repair or replacement.

Moreover, it is vital to schedule regular maintenance checks to prevent damages or the need for full replacements. Timely repairs and maintenance save time and money in the long run. Customers can always count on reliable and professional heating and cooling services, such as the trusted AC Repair Phoenix services within their reach for quick, efficient, and affordable solutions to their cooling needs.

Five Facts About the Resistance of the Oven Heater Element:

- ✅ Resistance is the opposition to the flow of electric current and is measured in ohms (Ω). (Source: All About Circuits)

- ✅ The resistance of the oven heater element is determined by its length, diameter, and the resistivity of the material it is made of. (Source: ScienceDirect)

- ✅ The resistance of the oven heater element can be measured using a multimeter and should fall within a certain range. (Source: RepairClinic)

- ✅ If the resistance of the oven heater element is too high, it may result in insufficient heating, while too low resistance can lead to overheating and damage to the element. (Source: United Servicers Association)

- ✅ Proper maintenance, cleaning, and inspection of the oven heater element can help ensure its optimal performance and prolong its lifespan. (Source: HomeTips)

FAQs about What Is The Resistance Of The Oven Heater Element?

What is the resistance of the oven heater element?

The resistance of the oven heater element varies depending on its size and model. However, the typical resistance range for an oven heater element is between 20 and 50 ohms.

Why is the resistance of the oven heater element important?

The resistance of the oven heater element determines how much current flows through it and ultimately how hot it gets. If the resistance is too high, the element may not heat up enough, and if it is too low, it may overheat and burn out.

Can I replace the oven heater element myself?

It is possible to replace the oven heater element yourself, but it is not recommended unless you have experience with electrical repairs. Working with high voltage can be dangerous, and improper installation can result in damage to your oven or a fire hazard.

How do I know if my oven heater element needs to be replaced?

If your oven is not getting hot or is taking too long to heat up, the oven heater element may need to be replaced. You can also visually inspect the element for any signs of damage or burning.

How much does it cost to replace an oven heater element?

The cost of replacing an oven heater element varies depending on the model and size of your oven. However, on average, the cost for parts and labor can range from $150 to $300.

Can I prevent my oven heater element from burning out?

To prevent your oven heater element from burning out prematurely, make sure to clean your oven regularly and avoid using it for self-cleaning cycles too often. You should also avoid putting heavy or wet dishes on top of the element, which can damage it.